T-SIM example 1

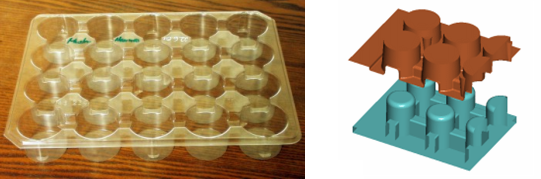

This example shows T-SIM used as an optimization tools for processing conditions tuning. The part, a transportation tray, is produced using plug assisted thermoforming.

|

Tray - process optimization The transportation tray is made of PET, the initial sheet thickness was 0.8 mm. The task was to achieve an optimum thickness profile, which would result in acceptable / required mechanical properties. The optimization procedure focussed on the final plug depth, i.e. the only modified parameter in this optimization was the final plug position. |

Final plug position influence - simulation analysis

Four final plug positions were used for simulation in order to see the final plug position influence on the final thickness profile:

| Bottom | Plug stops 1 mm from the mold bottom |

| + 1cm | Plug stops 11 mm from the mold bottom |

| + 2cm | Plug stops 21 mm from the mold bottom |

| + 3cm | Plug stops 31 mm from the mold bottom |

Four projects were calculated and post-processed in order to get thickness values for proper analysis along the following cut:

Comparison of the simulated thickness profiles is shown on the following figure:

From the comparison, it can be deducted that the optimal final plug position should be somewhere between the mold bottom and 11 mm above the mold bottom.

Final plug position influence - experimental analysis

To test the agreement of simulation and experimental results, four samples produced with four different final plug positions (identical to those used in simulation) were measured and the measured thickness values were compared with the simulations. The calculated results are shown in the following four graphs:

|

|

|

|

The final optimized plug position was expected to be somewhere between the mold bottom and 11 mm above the mold bottom. The best (optimal) results were obtained with the final plug position 5 mm above the mold bottom.

This case study shows how T-SIM can be used in the plug assisted thermoforming optimization. Not only the final plug height, but also the plug shape / dimensions can be modified and tested on PC instead of wasting material and time in the real production.

The comparison of simulated and experimental results shows that T-SIM is really capable to give good enough predictions even in cases of complicated shapes produced using plug assisted forming.

This example is a courtesy of Mr. Hannes Jacob and Mr. Manfred Jacob, Manfred Jacob Kunststofftechnik GmbH & Co. KG, Germany.